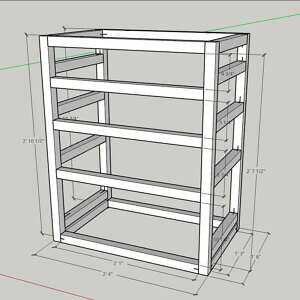

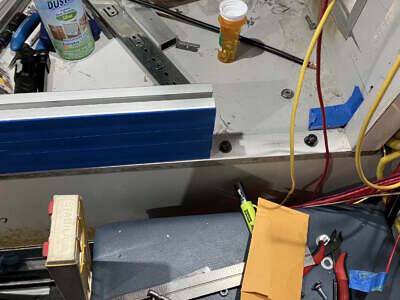

Using one of the lockers for tool and supply storage. Ultimately, I plan to use the locker directly behind the driver as my tool locker.

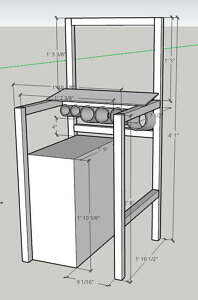

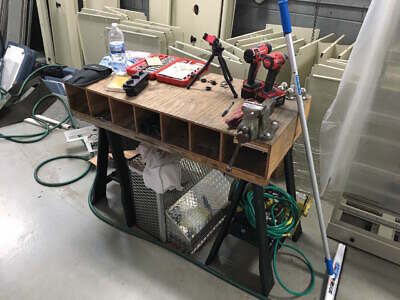

Using two cheap HarborFreight saw horses, I repurposed the wooden spare oxygen cylinder holder that was left in one of the truck lockers into a makeshift workbench. Also mounted my Dad’s bench vise on it.

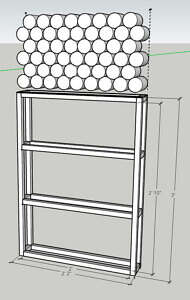

Using this locker to store cleaning supplies and some spare tools on the top shelf. The bottom shelf is more tool storage and various parts I’m working on. Ultimately this will be the plumbing closet.

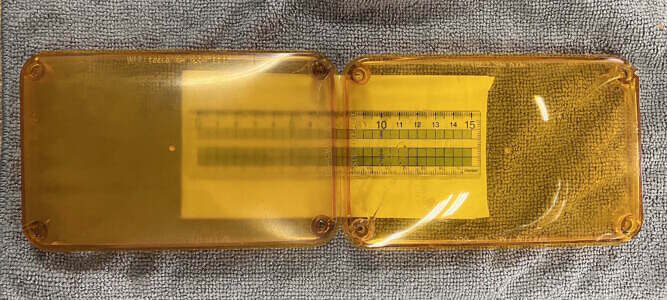

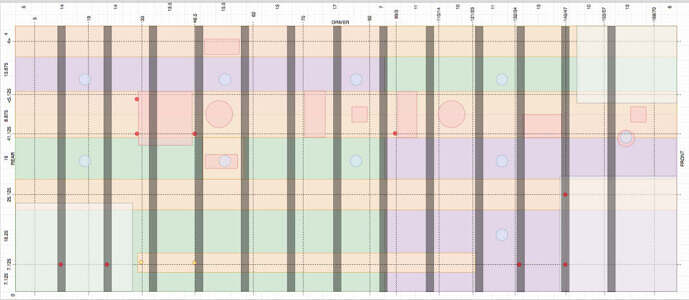

Polishing right half of extended cab window with cerium oxide. Looking closely, you can see the reflection of a window in the lower half of this window. The grey, splotchy lines are the subject water spots.

Cerium oxide polishing test results. Left half of window is unpolished while right half has been polished. It’s probably nearly impossible to tell, but if you look at the reflections of the windows, the two on the left have grey blotches, which are the water spots described.

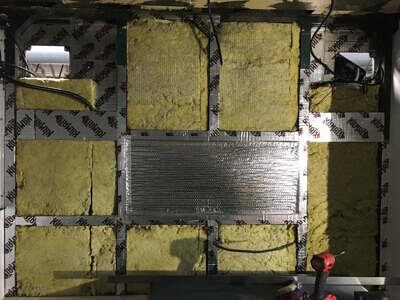

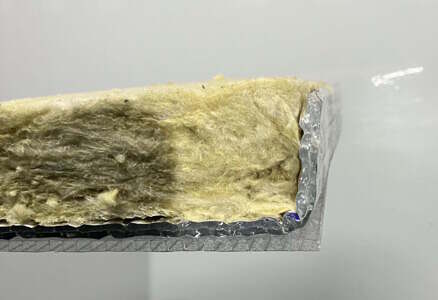

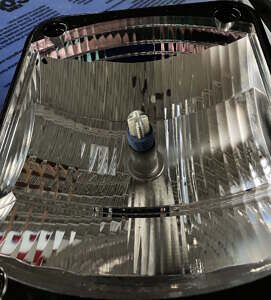

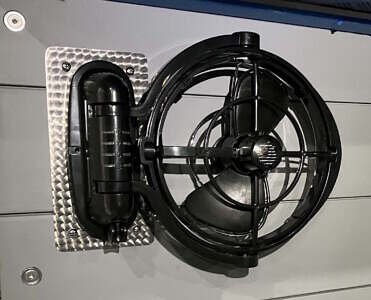

Showing mineral wool and Reflectix insulation. The door latch mechanisms are wrapped in Reflectix to minimize potential jam issues with the Mineral wool.

Looking back into the extended cab from passenger seat. Kilmat applied to the Robinson cabinet and ceiling structure. Where the ceiling structure was gusseted I used 1/4″ neoprene insulation.

Looking rearward from passenger seat. The cab floor has all kinds of lumps and channels, which make it somewhat precarious to walk on.