Water storage was another part of this project I had to plan for. I had set the arbitrary goal of being self sufficient for 30 days, just to give myself a design target. To come up with my water storage needs I spent several days measuring my average water consumption and, er, liquid production. I’m not particularly wasteful with water, but I haven’t worried about taking an extra long hot shower or whether I turn the faucet off when I brush my teeth. Now that water will be a very limited resource, I expect to be more conscious about my usage of it, which is surely not a bad thing. I ran repeated experiments taking “Navy” showers and calculating how many times, on average, I might wash my hands in a day, how much would be used for cooking, etc.

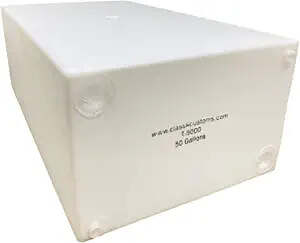

The most common method of vehicle water storage is molded plastic water tanks. These are typically rectangular containers that come in an almost infinite variety of sizes and often have spouts for filling, draining and venting molded into them. Being a ladder frame medium duty truck meant that I had plenty of room under the truck to mount all manner of tanks and given my truck’s hauling capacity, weight was never going to be an issue. However, the downside of these plastic storage tanks is they obviously require plumbing to move the water around. This adds complexity and creates many more potential points of failure. My thought process when designing something always involves considering maintainability. That is, how hard is it going to be to service it, clean it, etc. Having a built-in tank storage system typically also requires some sort of a fill system. This requires a hose, drilling more holes in the vehicle for the intake and vent valves, not to mention the tanks mounted under the truck would be difficult to clean and sterilize. I still plan to mount a tank for grey water storage as well as a dedicated “yellow” tank, but along the way I decided to go a different route when it came to storing fresh water. I will not have a blackwater tank, which I will address in another post.

Everlanders, One of the YouTube channels I follow, made a post about how they used ball-lock kegs (aka Pepsi, cornelius or corny kegs) for water storage (video here), which I thought was pretty dang clever. These are 5 gallon stainless steel kegs with ball-lock fittings used in home brewing and restaurant soda machines. They are approximately 9″ in diameter and 26″ tall. They can be pressurized, eliminating the need for a water pump and have a large access port on top to make cleaning them relatively easy. Filled with water, they weigh 55 pounds each, which makes them easy to move around by hand (they also have big, heavy duty rubber handles.) Being stainless steel, they would also be far more durable than molded plastic and not impart a plastic taste or leach chemicals into the water. Brand new they can be fairly expensive, but I found a company online (CornyKeg.com) that sells refurbished kegs at roughly $55 apiece. In total, 40 gallons of keg storage will be a little more expensive than plastic tanks, but once you figure in all the plumbing pipe and fittings, etc that I’ll avoid having to buy, it probably comes out about the same. The used kegs are a little scuffed on the outside, though being stainless steel will be easy to polish up. They have been cleaned inside and all the seals pressure checked before shipping. What really appealed to me, besides the massive reduction in complexity, is that I can add to or subtract from my water storage as needed. If I find 40 gallons isn’t quite enough, I can easily fit another two kegs into a locker. To start, I’m going with eight kegs, which will give me 40 gallons of fresh water. I’ll also have a couple of 20 liter plastic containers for storing rain water or hauling water from rivers or lakes. I’ll probably also keep one of those in-fridge jugs that holds a few gallons as a backup. I can do all the measuring and estimating in the world, but until I get out there and start actually living in the truck I can’t know exactly what my water usage will be.

The kegs can be pressurized with an air pump, which I conveniently already have and daisy-chained together. Being a standard size I can also easily move them to different lockers if I need to redistribute weight around the vehicle. With the kegs I can use any water hose within reach or easily pull them out and carry them to the water source instead. My plan at present is to have four kegs (20 gallons) daisy-chained together in my utility lock to serve water into my kitchen faucet. The other four kegs will be backup storage and can be swapped into the system as water is used. Conveniently, of the eight kegs I received, one of them has a green instead of black handle. This will be my reserve keg and act as a visual reminder that I’m down to my last 5 gallons of water.