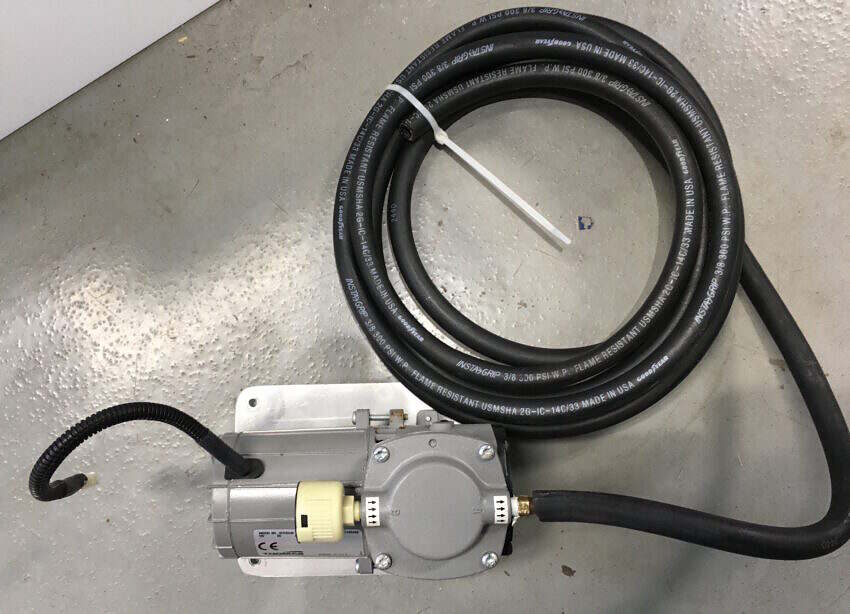

As a former ambulance, my truck came equipped with a number of devices that I initially thought would be useless. One of those was the suction pump for what’s called the inhalation station. This is the small counter next to the attendant’s seat where a patient could be administered oxygen or have their airway cleared through the use of a suction pump. The pump itself was actually located in the outside locker I’m calling my plumbing locker. It was mounted on the underside of the locker ceiling on rubber bushings, which I assume was to reduce vibrations from the motor being transferred to the ambulance panels. There was a large, heavy duty hose that ran from the back of the inhalation panel manifold to the pump. Before anyone gets grossed out, it’s my understanding that the suctioned fluids went into some kind of disposable container mounted in a bracket at the inhalation station. The pump merely provided vacuum into that container.

Thar She Blows!

I was absentmindedly staring at the suction pump the other day and noticed that the hose fed into a fitting with arrows indicating flow into the pump while on the opposite side was what I assumed to be an air filter/muffler with arrows indicating flow out. Knowing absolutely nothing about pumps, it occurred to me that perhaps a pump is a pump and whether it sucks or blows is simply a matter of which side of the pump you’re on. I unscrewed the hose fitting and swapped it with the air filter/muffler fitting and wouldn’t you know it, when I applied 12V to the pump it started pumping air from the hose!

It’s a small pump and I don’t think it will make enough pressure to pump the truck’s tires, which require 110psi, but it might work for topping off bike tires. I’m researching adding a regulator and small reservoir tank for just that purpose.