Strap in for everything you never wanted to know about diesel engine Exhaust Gas Re-circulation (EGR) systems. I should preface this with the disclosure that I am not an expert, nor do I claim to be. In fact, my diesel engine knowledge was essentially nil when I started this project, so this is basically a recap of my understanding of EGR as it specifically relates to my truck and engine based on watching a couple dozen hours of YouTube videos and pouring over the 1500+ pages that comprise the service manual and diagnostic troubleshooting guide for MaxxForce engines. Your mileage may very. Ha! Get it? Mechanic humor achievement unlocked.

If you read my Diesel vs Gasoline post you no doubt have a vague, child-like understanding of the benefits of diesel engines and are all the dumber for it. The downside to all that high-torque, diesel-wonderfulness is that due to the nature of diesel fuel, which is more energy dense than gasoline, diesel engines produce more soot, or unburnt fuel, and combustion by-products. This is obviously a concern for the environment, though other than jackasses in lifted pickups with self-confidence issues “rolling coal” to feel better about themselves, diesel engines spew a lot less black smoke than they used to. This is due to EPA regulations and the resulting technologies manufacturers have implemented to meet said regulations.

Since around 2011 all diesel trucks built in the U.S. have required Diesel Exhaust Fluid (DEF) systems to meet ever-increasing government mandated emissions standards. DEF, so-called government juice, is little more than water and urea (a component of urine…I shit you not), which is sprayed into the exhaust in the after treatment section of the exhaust system to reduce nitrogen oxides. As I understand it, DEF is not particularly expensive, especially when compared to diesel fuel, but the DEF system adds complexity, which makes the truck more expensive to maintain. Not to mention that accidentally adding DEF to your diesel fuel tank is a catastrophically expensive mistake (DEF tank caps are typically blue, whereas diesel tank caps are either green or labeled as “Diesel”.) Even after doing research, the timeline of DEF implementation is still not perfectly clear to me, but the short version is my 2011 model year ambulance is based on a 2010 chassis and engine, which is pre-DEF. Given all that, I thought I was being particularly smart by buying a pre-DEF truck, when in fact, as a lifetime of experience should have taught me, I was being particularly stupid.

What was unknown to me at the time is that DEF systems were just one small piece of the attempts to reduce diesel emissions by the federal government. Prior to DEF and the EPA 2013 requirements, manufacturers had to comply with EPA 2010 requirements and EPA 2007 before that. This was primarily accomplished using EGR (Exhaust Gas Re-circulation) systems to essentially recycle exhaust gases so the combustion cycle could burn off more of the unburnt fuel before finally spewing the remainder into the atmosphere.

In 2007 Navistar, the parent company of International, designed a highly computerized (and thereby complicated) EGR system in an effort to comply with emissions regulations. They named these engines MaxxForce, with different models based on the output of the engine (DT, 7, 9 ,10.) Where I got confused, mostly due to a lack of due diligence on my part, was that Navistar had previously made an engine called the 466DT, which is widely considered to be one of the most venerable and reliable diesel engines ever made, with a history going back to the late 1920’s. It was so durable and widely respected that I’ve read about it being called “The Legend”. I took all the praise heaped on the DT466 and assumed it applied to the revised version called the MaxxForce DT, which it most assuredly did not. It turns out the early MaxxForce engines had a number of design flaws in the EGR system that caused frequent, premature maintenance problems. Ultimately, they resolved many of the technical issues, but also settled a class action lawsuit in the neighborhood of a cool billion dollars as a result of the debacle. Besides the design flaws, which were corrected in later engines and retrofitted in affected engines, the engine and EGR system is also extremely computerized, which adds to it’s reputation for being complicated. The early problems and complicated EGR system combined to give the MaxxForce engines a rather bad reputation among truck drivers and many diesel mechanics.

However, I’ve also read articles, by independent sources, that praise the MaxxForce DT as a continuation of the legacy of the 466DT. From what I’ve read, while the complicated emissions system does make it a challenge to work on, the core of the engine itself is extremely durable and well built. Basically, it’s all the accessories, sensors and wiring attached to the engine that are often the problem, not the block or the core engine components like the pistons, injectors and head.

The whole issue of diesel emissions stems from a couple of factors. If diesel engines run too hot, they create a lot of nitrogen oxides, which are bad for the environment and the people and animals who enjoy breathing in it. If they run cooler, they create fewer nitrogen oxides, but as a result are less efficient at burning all the fuel during the combustion cycle, which has the undesirable effect of creating more soot. Soot is bad for the environment and bad for the engine.

Enter the Regen

Whether equipped with EGR or DEF systems, diesel engines still make more soot than is desirable. Rather than just spewing this out the exhaust pipe as they did in times past, this soot is now captured in something called a Diesel Particulate Filter (DPF). Over time, the DPF fills up and eventually can become blocked, which creates back pressure into the engine, which can cause all sorts of problems. To avoid this, when sensors detect the DPF is getting full, the ECU (Engine Control Unit) will perform what is known as a self-regeneration (self-regen.) This process uses an additional fuel injector downstream of the engine exhaust flow to burn fuel so the air entering the DPF gets hot enough to burn off all that nasty soot and convert it to basic carbon that can be safely ejected out the exhaust system. Of course, this uses more fuel, which decreases the truck’s mileage, which increases costs. Now, if a truck is running at highway speeds, the engine will typically be at a high enough RPM long enough to generate enough heat that will, when combined with the downstream injection system, allow it to make temperatures high enough to successfully perform a self-regen when directed by the ECU. However, for trucks that don’t frequently run at highway speeds for long enough, they may have to do what’s called a parked regen or you guessed it; a parked regeneration. This requires the driver to park the truck and let it sit for 20-30 minutes while the engine revs up to generate enough heat and the regen process takes place. Doesn’t sound particularly efficient or environmentally friendly does it? It’s also important to note that whether the truck does a self-regen or commands the driver to do a parked regen, neither will reduce the DPF back to 0%. It might have to do several regeneration cycles to get it below 25%, which is generally considered acceptable to proceed. Periodically you also have to have your DPF baked, where it’s removed and baked at a high temperature and then cleaned. As one might expect, adding more complexity to an engine to monitor and perform regens increases the amount of maintenance needed. I suppose somewhere there’s a formula that shows the net effect of all this is less pollution, but it certainly seems wasteful.

The Delete

Now if all this sounds like a huge, expensive hassle that ultimately decreases engine performance, fuel efficiency and engine longevity, that’s because it is … and it does. Not unexpectedly, some diesel truck owners would prefer to avoid all this so they do what is known as a Delete. This entails removing various exhaust components and sensors and reprogramming or otherwise fooling the engine computer into not doing regens. This is of course frowned upon by the authorities and if you get caught doing it, my understanding is the penalties can be quite severe, especially for a commercial driver. The technology exists to detect excessive tailpipe emissions and simultaneously take a picture of the license plate all while at highway speeds, though other than California I don’t know for sure if any other states do this yet. If you’ve ever looked closely at weigh stations on the expressway you will notice that they are absolutely brimming with all kinds of sensors and cameras, so who knows what the authorities are monitoring. In fact, if you are the observant type you will notice sensor devices all over road signs, along Interstates and at intersections monitoring who-knows-what as we pass by.

Limp Mode

Manufacturers of diesel trucks have to abide by government regulations so they program their engine computers accordingly. If an ECU detects that something with the emissions system is out of spec, or if something is behaving in a potentially dangerous way, it will command the engine to de-rate, also known as entering limp mode. This will limit speeds from 20 mph to as low as 5 mph. It won’t leave you stranded (well, in some cases it actually will…), but you also aren’t going anywhere fast. This was the primary concern with my truck and the stop engine lamp I was getting when I picked it up in Florida. I’ve since come to understand that ambulances and fire engines may actually have a government-approved work around to a de-rate condition. This makes some logical sense: If you are rushing to an emergency or carrying a critically ill patient to a hospital, you don’t want to be stuck limping along at 20 miles per hour or be forced to endure a 20 minute parked regen because your engine might be creating a little extra pollution. This is almost complete conjecture on my part. I’m 99% sure I read this on some forum online, but I can’t for the life of me find it again.

MaxxForce

To sum up, I chose a truck with one of the most unreliable and unpopular engines. Well done, you idiot. Several people with far more diesel expertise than I, including the mechanic at the garage in Miami, told me the MaxxForce engine was problematic. Another advised me my best course of action would be to sell the truck and buy something with a Cummins, one of the most respected and reliable diesel engines. I also met a truck driver who cringed and made a face when I told him what engine I had. This was no doubt absolutely sound advice. But I was too dumb or too stubborn to heed it. There was a point back when I was sitting in my truck in the surplus yard in Pembroke Pines, sweating profusely, hungry, thirsty, tired, dirty and sunburnt, when I briefly considered this course of action. However, I had a number of reasons for deciding to stick with it. First, this was all part of the adventure. I could have inspected the truck before buying or done more research, so it’s not like I was fooled into buying this particular truck. Second, if I had known the full extent of the Maxxforce’s bad reputation before buying, I probably would have still gone through with it given that the rest of the truck was such a good fit for my requirements not to mention one helluva good deal (if buying a retired ambulance and converting into an RV could ever be considered a good deal.) After extensive research over the past two years I’ve also come to the conclusion that while not entirely undeserved, the MaxxForce’s bad reputation stems from several factors, some of which I suspect are are not valid when it comes to my particular truck. Since my truck was contractually maintained by a professional maintenance company that employed highly skilled EVT (Emergency Vehicle Technicians) it was safe to assume that my engine was generally treated well with timely oil changes and prescribed preventative maintenance (PM.) While I only have the the last three years of maintenance records because the city had switched maintenance companies, I was able to locate a contract agreement in the city commission’s meeting minutes and see the extent and frequency of the maintenance.

The EGR System

As the name suggests, the EGR system is all about exhaust gas recirculation. In order to understand the potential problems with this system and ultimately the problem I identified with my engine, lets follow the exhaust gas from the point it leaves the combustion chamber and see how it’s “recirculated”. I suppose the proper order would be to start with fresh air coming into the engine, but since we’re talking EGR it seemed more appropriate to start with the post combustion exhaust gases.

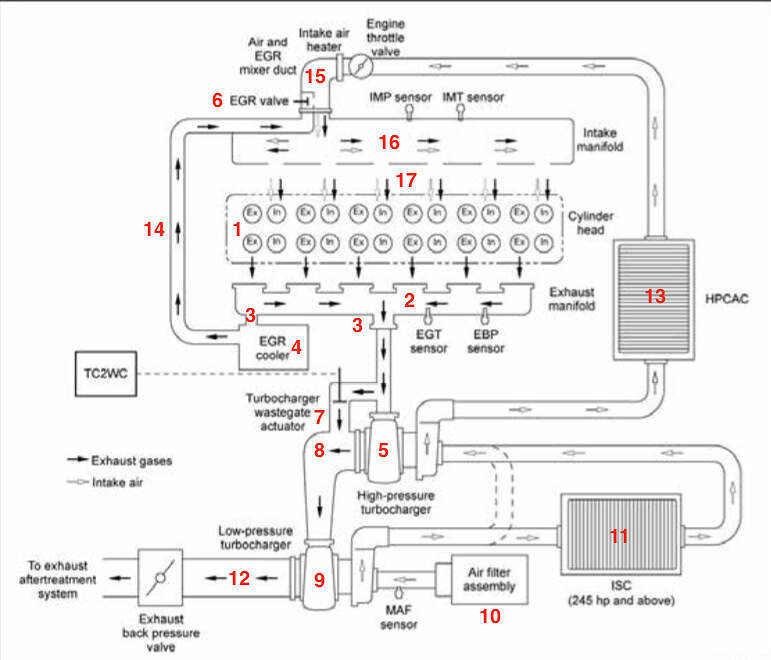

After combustion, exhaust gases leave the cylinders via exhaust ports(1) which feed into the exhaust manifold(2), which has two exits(3). A portion of the exhaust gas is ported into the exhaust gas cooler(4), which I’ll discuss shortly, while the remainder is directed to the high pressure turbo(5), depending on the position of the EGR valve(6) on the other side of the engine. Briefly, a turbo charger uses exhaust gas to spin a turbine which in turn pressurizes incoming fresh air which provides more oxygen for the combustion process and hence, more power. Because you have to have exhaust gas first in order for a turbo to spin up fast enough to pressurize the incoming air, there is a slight delay, so-called turbo-lag, between the time you press the gas and the engine makes enough exhaust gas to spin the turbo up and begin providing boost. This used to be a thing back in the 80’s, at least in passenger cars, when you would get a huge boost of power after a couple of seconds after you mashed the gas pedal. Since the 90’s computers, variable geometry turbos or dual scroll turbos and hybrid electrical systems have all but eliminated turbo lag. To further complicate things the turbo doesn’t require all the exhaust gas it’s being sent all the time so there is a waste gate valve(7), controlled by the ECU, where excess exhaust gas is diverted around the high pressure turbo. These two flows are then recombined(8) after the high pressure turbo where they are directed to the low pressure turbo(9). The low pressure turbo uses this exhaust flow to spin it’s turbine which sucks in fresh air through the air intake(10), pressurizes it and sends it to the interstage cooler(11) after which it’s delivered to the high pressure turbo(5) for, you guessed it, more pressurization before being piped to the high pressure charge air cooler(13). Once the exhaust gas leaves the low pressure turbo it’s directed to the exhaust aftertreatment system(12). The reason for the interstage cooler(11) and charge air cooler(13) is because when you pressurize air, it gets hot and basic physics teaches us that hot air is less dense than cold air. In order to cool the pressurized air and increase density, it’s directed through the Charge Air Cooler(13), which uses a heat exchanger circulating with coolant to cool the air.

Now lets get back to the exhaust gas cooler(4) that handles the other half of the exhaust gas coming out(3) of the exhaust manifold(2). This is a heat exchanger, where hot exhaust gas is passed over a dense pattern of fins cooled with engine coolant, which in turn removes heat from said gas. The exhaust gas cooler as originally designed on the MaxxForce engines had some engineering design flaws which caused it to fail prematurely and expensively. The redesigned part corrected those flaws and there are now third-party companies which make exhaust gas coolers using advanced manufacturing techniques to make it even more efficient and reliable. The now cooled exhaust gas takes a quick trip around the rear of the engine via the exhaust gas crossover pipe(14) where it’s directed to the EGR Valve(5). The EGR Valve is mounted in something called the mixer duct(15). It’s job is to mix in the desired combination of cooled exhaust gas with the compressed fresh air coming from the charge air cooler(13) before introducing it into the intake manifold(16) where it’s supplied to the cylinders for combustion(17). The exact ratio of exhaust gas and fresh air is continually adjusted by the ECU via the EGR Valve based on the power demands on the engine.

While I’m sure all this has been fascinating to learn, we now come to the interesting part with regards to my truck. One of the three fault codes it was throwing was a stuck or failed EGR Valve (the other two were far less concerning, relating to ABS on the brakes and the HVAC climate control for the cab, neither of which would leave me stranded.) I reasoned that when the truck is started, the ECU does all it’s checks of the myriad of sensors in the engine and then tries to cycle the EGR valve to ensure that it can control the exhaust/fresh air mixture. If this test fails, it throws a fault code because the engine would either not be using enough exhaust gas, thus creating more pollution or not using enough fresh air, potentially causing a loss of power or introducing too much soot back into the engine. While in Florida I was able to identify the location of the EGR Valve, but wasn’t able to remove it for inspection. This created my main concern, given my extremely limited understanding at the time, which was the engine might possibly de-rate, leaving me in limp mode or worse somewhere between Florida and Michigan.

If I didn’t already detail it in a previous post, this is why I ultimately decided to leave my truck at a diesel repair shop in North Miami. However, they were busy rebuilding and repairing engines for customers that actually earned their livings with their trucks so I got the distinct feeling mine was not a high priority, which I couldn’t really blame them for. During the ensuing three or so weeks, I dove into the engine maintenance and diagnostic manuals and gained a much better understanding of what was going on. While the garage in Miami half-heartedly diagnosed the EGR cooler as the culprit and offered to get me bumped to the front of the line at the nearby International dealer, I wasn’t convinced despite my obvious inexperience. I reasoned that both the EGR Valve and the EGR Cooler were important enough components on completely opposite sides of the engine that they would surely throw separate and distinct error codes. Since I was not seeing any active or past error codes related to the EGR Cooler I became convinced it was the EGR Valve. As mentioned, I did try to remove the EGR Valve while I was in Florida, but it was stuck in place and I didn’t want to make things worse by potentially damaging it. This was post-COVID as well so supply chain delays could mean that even if the dealership diagnosed the problem, my truck could be sitting there for weeks waiting on parts.

The EGR Valve

This is what my EGR Valve looked like upon removal.

Fast forward to two years later after successfully traversing the 1600 miles north with a bad EGR valve and I decided to have a look at the valve myself. Removing it from the air mixer duct requires a specialized puller tool. I happened upon a YouTube video of a guy who designed and manufactured a simpler puller tool he sells on eBay for $125. This tool worked perfectly, although I still felt the EGR valve housing snap during removal. However, this appears to be because the end of the housing was seized in the air mixer duct rather than the fault of the tool. Once removed, I was able to see that my EGR Valve was in terrible shape, appearing as though it had been fed through a garbage disposal. It’s internal parts were corroded almost beyond recognition and it’s advanced state of decay was all the confirmation I needed that the EGR Valve was indeed the source of the fault code. This was later confirmed by the International dealer in Grand Rapids where I had the truck serviced. Because the broken part of the EGR Valve was stuck in the air mixer duct I ended up having to have both replaced.

Not to mislead you, dear reader, into thinking I brilliantly solved my engine problem and drove happily off into the sunset. This is my dumpster fire, after all, and that was merely one engine problem that was throwing a fault code, not THE engine problem. It turns out I had much more expensive problems lurking under the hood…