There is a leak located on the underside of the brake fluid reservoir where it connects to the master cylinder. Because the assembly is mounted high up and against the firewall in front of the driver the brake fluid has coated all the fittings, harnesses and other hardware below it, down to the left leaf springs. Anywhere it has contacted paint, it has bubbled it leaving the exposed metal to rust. Thus far, it’s all surface rust and it doesn’t appear to have had any effect on the truck frame itself, just the painted brackets and leaf spring assembly.

The leak is relatively small, I’d estimate 4-6 drops per hour, but that adds up to a surprising mess. Now that I’ve located where it’s leaking from I’m capturing the drips in a small container while I research the options to fix it. I’ve also started to de-grease and wipe down the areas contaminated with brake fluid.

A little background on the brakes in the truck. It’s equipped with a WABCO Full Power Brake system (FPB), which is a nitrogen-charged, hydraulic system with four disc brakes as apposed to more traditional service air brakes with brake drums found in most medium and heavy duty trucks. The parking brake is a separate air actuated system. One of the big advantages of the FPB system, besides ABS, which all trucks must have, is Automatic Traction Control (ATC) and Electronic Brake force Distribution (EBD). Similar to what ABS does for stopping, ATC does for traction when accelerating. If the system senses one of the drive wheels slipping it will apply differential braking to that wheel.

The downside is it’s a complex system pressurized to 2300 PSI, making it rather difficult and potentially dangerous to work on. In most passenger vehicles, pressing on the brake pedal actuates the master cylinder which sends brake fluid to the brakes at each wheel (this is a gross oversimplification, but adequate for purposes of this post.) In the WABCO system, pressing the brake pedal causes the master cylinder to push brake fluid through primary and secondary high pressure relay lines to the Hydraulic Compact Unit (HCU) located under the truck. This is where the brake computer lives and controls braking to the four wheels via second reservoir and individual high pressure lines and wheel speed sensors. The system uses two nitrogen-charged accumulators to store energy supplied by redundant hydraulic pumps.

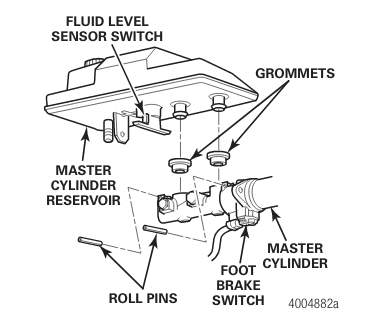

The fluid leak is originating from the left grommet in the image above, though they may both be leaking to some degree.

Unfortunately, while the grommets themselves are only about $15, it’s necessary to depressurize the entire system in order to replace them. Doing that requires bleeding the system of air once it’s refilled and re-pressurized. I haven’t figured out yet if it’s even possible to do this without the WABCO Toolbox software to talk to the HCU. It also may be less expensive to simply replace all the components that commonly have wear, which includes the master cylinder, master cylinder reservoir, HCU reservoir and accumulators. I still have to check past maintenance records and see if any of those were replaced.