The ambulance came equipped with pairs of fixed, halogen lights on the left, right and rear of the module. These were used to light the area surrounding the vehicle when “on scene”. Each individual light head had a 60 watt halogen bulb, a chrome reflector and diffusing lens in addition to the rubber weather strip to seal it against the truck wall. While I planned to retain these lights, I wanted to convert them to LED in order to conserve power and reduce the heat signature as I was going to have them run off my house battery bank rather than the chassis batteries. A 5-6 watt LED has the equivalent output of a 60 watt halogen, while using much less power and producing less waste heat. Along the way I decided that I didn’t need 120 equivalent watts per side and settled for a 3 watt LED, which is rated as equivalent to a 20-30 watt halogen. This meant I could power all 6 scene lights using a third of the power of what it previously took to power just one halogen bulb.

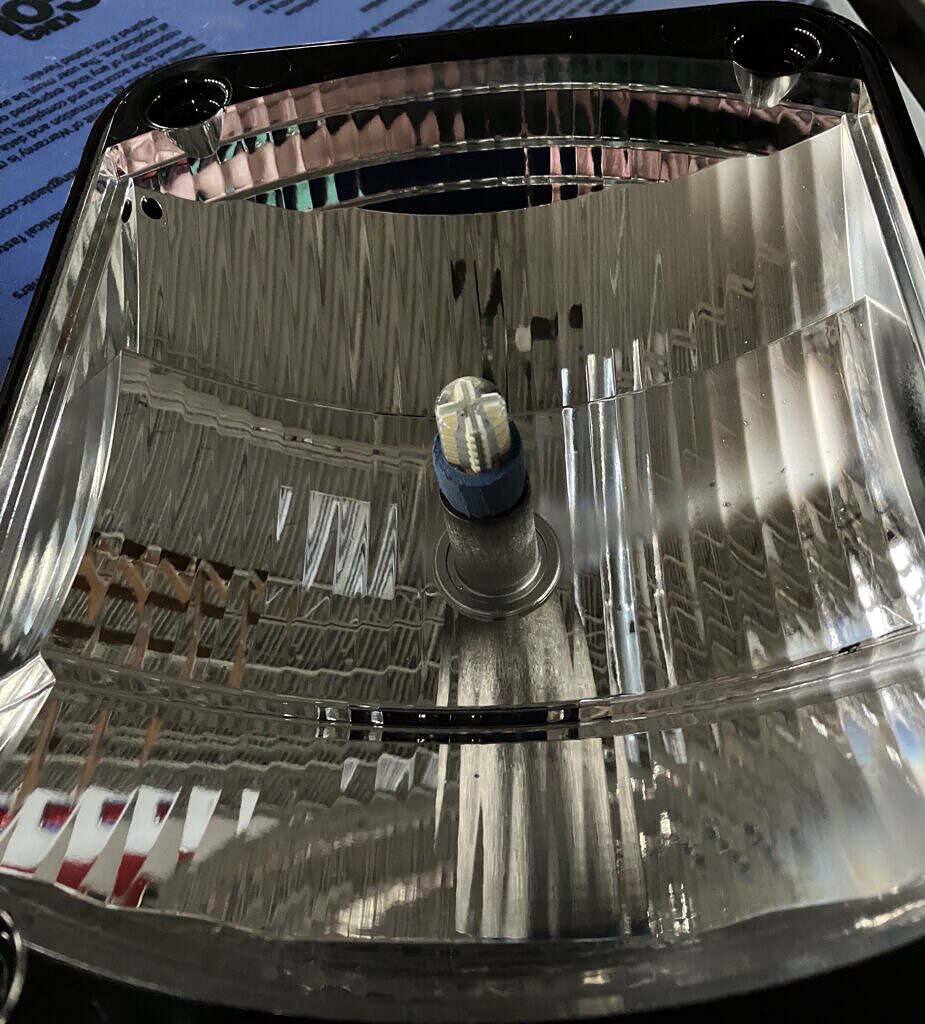

The one issue I faced was that the posts on the LED bulbs didn’t match those on the halogen bulbs. The scene lights, like all the other emergency strobes, were made by a company called Whelen Engineering and had proprietary bulb fittings, even though the bulbs themselves appeared to start out as common halogens. After some research and a YouTube video or two, I came up with a way to adapt the LED bulbs that involved crimping and soldering on some larger posts and fitting the bulb into the rubber insulator from some 2/0 wire I had left over from wiring the battery bank. This “assembly” would then fit snugly into the light’s bulb socket. I did some informal testing that essentially involved shaking the light head and knocking it against the table that satisfied me that this would work. Since these aren’t driving lights and I don’t expect to use them when the truck is in motion, if they ultimately vibrate loose, I’m not all that concerned. If that happens I’ll add some glue to hold them in place.

While I wasn’t particularly concerned about water ingress, I did opt for sealed LED bulbs. These are molded into something that appears to be silicone, making them waterproof.

As the scene lights were going to run off my house batteries rather than the engine, I needed to make some wiring changes as well since I wanted each side pair on it’s own circuit. When the ambulance was built they had wired each individual light on it’s own circuit, even though they tied each pair together back at the electrical bus. However, like nearly all the other DC loads, they used chassis grounds, which I had decided against. That meant that while I had a positive wire for each light running back to the wiring cabinet, I didn’t have a ground. In order to minimize the amount of new wire I had to run I wired each pair in series and used the second light’s existing load wire as the ground. The existing wires were 18 gauge, which was more than adequate for the comparatively small amp load the LEDs would require.