Way back when I was working in the surplus yard in Pembroke Pines inspecting and prepping the rig for it’s maiden voyage north I had found that the cab mounted emergency light bar had been removed as part of the decommissioning process. I noticed it in a pile of various lightbars, controllers, police car cages and laptop stands on a nearby pallet. Since it was in the original pictures when I purchased the truck, and therefore part of the deal as far as I was concerned, I asked the fleet manager if I could have it. He kindly said that not only could I have the lightbar, but I could have anything else I wanted from the pile of equipment. I didn’t want to be too greedy, so other than the lightbar I only snagged an in-car laptop mount.

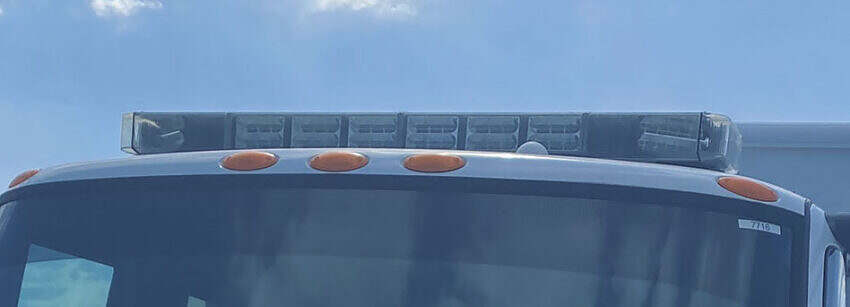

The lightbar, made by Whelen Engineering Company, is a 55″ Freedom model composed of red and white strobes; six forward facing, two side facing alley lights and two forward 45 angled strobes. It’s designed to be modular so that depending on the application the end user could fit different lightheads (fire truck, police cruiser, tow truck, etc.) Early on I had a vague idea to convert the lightbar into a trail light of sorts, though admittedly at the time I hadn’t the faintest idea how it worked. The lightbar, as configured, had two white Whelen 400 series lightheads and two white corner strobes with the remainder being red strobes. Eventually I plan to convert the four red strobes to white LEDs, but initially I decided to just rewire it enough so I could have a set a forward facing white lights in addition to the corner lights. I found a used pair of white lightheads, which will mount in the side-facing “alley” positions. As I’ve detailed elsewhere (I think), it’s illegal to posses red, white or blue strobes, but I found I could easily make the white strobes “always on”. The Whelen Freedom has it’s own built-in circuit board, but as it was proprietary (meaning I have no idea how it works and there is no documentation available) I decided to completely bypass it. Each light head, except the corners, is composed of two individual boards with six surface mount LEDs, each of which draw 1 amp. I ran a single 12V positive and negative to the lightbar through the existing hole in the cab roof and then used common busbars to distribute the power inside the lightbar to each lighthead, which would be switched in pairs. In order to control the lights, I used standard, 5 pin, Bosch-style relays so that I would only have to pass a single signal wire for each light circuit from the dash mounted switch up to the lightbar. For the cable I was able to re-purpose the original signal cable that connected the lightbar to the controller.

As one might expect for emergency equipment, the lightbar is a solid piece of engineering and the overall frame is made from a single massive piece of extruded aluminum. I was able to pull the manual from Whelen’s website and from that I figured out how to disassemble it. I found that there would be plenty of room inside as the rear section, which would normally house rearward facing lights was empty except for a mounted circuit board.

As with most of the other lightheads, the clear plastic lenses had some sun damage, but polished up quite nicely. I also plan to make a fitted cover out of duck cloth to cover the lightbar when parked for any length of time in order to protect the clear lenses from yellowing again.